Leave Your Message

In the modern culinary landscape, the demand for efficient food preservation methods has become increasingly significant. As a crucial component in maintaining flavor, nutrients, and shelf-life, the Vegetable Dryer Machine stands out as an essential tool for both commercial operations and home kitchens alike. Leading expert in food processing technology, Dr. Emily Carter, emphasizes the importance of these machines by stating, "The right vegetable dryer not only enhances the quality of dehydrated produce but also offers significant energy savings, making it an indispensable asset for any food preservation endeavor."

As we explore the top vegetable dryer machines available in 2025, we will delve into the best options that prioritize efficiency and effectiveness in dehydration. Whether you are a professional chef seeking to elevate your dishes or a health-conscious individual looking to create nutritious snacks at home, understanding the features and capabilities of these machines will guide your choice. The technology behind vegetable drying has evolved significantly, ensuring that users can achieve optimal results with minimal effort.

Join us as we unpack the nuances of the Vegetable Dryer Machine sector, highlighting the innovations and advancements that make these machines vital for anyone interested in sustainable food practices and delicious, preserved produce.

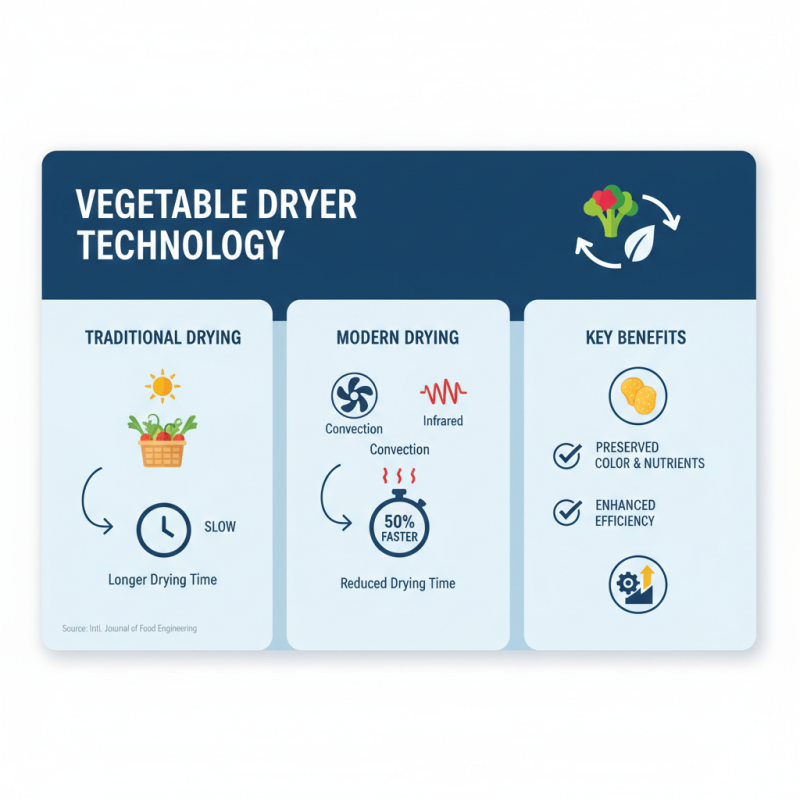

When choosing a vegetable dryer machine, several key features can significantly impact the efficiency and quality of the dehydration process. One critical aspect is the drying technology used in the machine. A report from the International Journal of Food Engineering indicates that machines utilizing convection and infrared drying methods can reduce drying time by up to 50% compared to traditional methods. This rapid drying not only preserves the color and nutrients of the vegetables but also enhances the overall quality of the end product.

Another vital feature to consider is the machine's capacity and versatility. With the global vegetable dehydration market expected to reach over $4 billion by 2025, consumers are increasingly looking for machines that can handle a variety of vegetables and produce consistent results. Efficient machines often come with adjustable temperature settings and airflow controls, which allow users to optimize the drying process for different types of produce. Furthermore, energy efficiency has become a paramount concern, with studies showing that energy-efficient models can reduce operational costs by 30% annually. Investing in a vegetable dryer that combines these features can lead to a more sustainable and productive dehydrating experience.

In 2025, the market for vegetable dryer machines has diversified to cater to various consumer needs, emphasizing energy efficiency and high output. The main types include convection, freeze-dry, and infrared dryer machines. According to a recent industry report by Grand View Research, the global food dehydration market is projected to reach USD 7.3 billion by 2026, with vegetable dryers being a significant contributor. This illustrates the growing interest in preserving the nutritional value of vegetables while reducing food waste.

Convection dryer machines utilize hot air circulation to draw moisture out of vegetables, making them suitable for large-scale operations. These machines vary in size and capacity, accommodating both small businesses and large manufacturers. On the other hand, freeze-dry machines are gaining traction for their ability to retain flavor and nutrients better than conventional methods. A study by Technavio indicates that the freeze-drying segment is expected to witness a CAGR of over 6% during the forecast period, highlighting an increasing preference for high-quality dehydrated products.

Infrared dryer machines represent a newer technology in the market, employing infrared radiation to heat vegetables directly, thereby enhancing energy efficiency and reducing drying times. Industry analysts predict that as energy costs rise, infrared dryers will become more popular due to their reduced operational costs. With consumer demand for dehydrated vegetables on the rise, these diverse types of dryer machines are well-positioned to meet the challenges of efficiency and quality in food preservation.

The efficiency of vegetable drying has gained significant attention as the food industry seeks innovative methods to preserve nutritional value while extending shelf life. Two predominant techniques, air drying and heat drying, offer distinct advantages depending on the specific requirements of dehydration. According to industry reports, air drying, while energy-efficient, can take several hours and may result in nutrient loss due to prolonged exposure to ambient air. In contrast, heat drying, which utilizes controlled temperatures, can reduce drying time substantially, making it more suitable for large-scale operations.

A recent analysis by the Food Processing Technology Journal highlights that heat drying can achieve moisture removal rates up to 10% faster than air drying at comparable energy inputs. Additionally, the retention of vitamins and minerals is notably higher in heat-dried products, with some studies showing up to 20% more retained nutrients in vegetables dried using this method.

This efficiency not only benefits the end consumer by delivering healthier products but also increases profitability for producers by minimizing energy costs and time spent on the drying process. As the demand for dehydrated vegetables rises, understanding the nuances between these drying techniques becomes crucial for optimizing production methods.

Maintaining a vegetable dryer machine is essential for ensuring its longevity and optimal performance. According to industry reports, a well-maintained dryer can enhance operational efficiency by up to 20%. To achieve this, regular cleaning is crucial. Residues from previous batches can compromise the quality of future dehydrated products and lead to mechanical issues. Operators should clean the machine's components, such as the drying trays and fan, frequently to prevent buildup and keep the airflow unobstructed.

Additionally, monitoring and calibrating the temperature settings can significantly extend the lifespan of a dryer machine. Overheating can cause permanent damage to various components, while maintaining appropriate temperatures can reduce wear and tear. Reports indicate that a significant percentage of dryer failures stem from improperly set temperature controls. Implementing a schedule for routine checks and recalibrations is a proactive approach that can mitigate risk and maintain efficiency. Lastly, it is advisable to adhere to the manufacturer's guidelines regarding operation hours and load capacities, as excessive use can lead to premature breakdowns.

| Model | Capacity (kg) | Power (W) | Heating Method | Price (USD) | Maintenance Tips |

|---|---|---|---|---|---|

| Model A | 10 | 800 | Electric | 150 | Clean vents regularly |

| Model B | 15 | 1000 | Gas | 250 | Check gas connections |

| Model C | 20 | 1200 | Hybrid | 300 | Inspect heating elements |

| Model D | 25 | 1500 | Solar | 400 | Keep solar panels clean |

When considering vegetable dryer machines for your home or business, it's essential to analyze the cost differences between budget-friendly and high-end options.

Budget-friendly vegetable dryers offer basic features and efficient performance at an attractive price point. These machines typically have lower wattage and may take slightly longer to dry vegetables, but they get the job done for occasional use or small-scale needs. They are ideal for those who want to explore dehydrating foods without a hefty investment.

On the other hand, high-end vegetable dryers come with advanced features that can significantly enhance the dehydration process. These machines often provide better temperature control, faster drying times, and larger capacities. They are designed for frequent use and can handle a variety of produce, ensuring consistent results. If you are serious about food preservation or planning to use the dryer for commercial purposes, investing in a high-end model can be worthwhile in the long run.

Tips for choosing the right vegetable dryer: First, assess your needs — consider how frequently you plan to use the machine and the volume of vegetables you typically dehydrate. Next, think about the available space in your kitchen since some high-capacity models can be bulky. Lastly, read reviews and check for warranties, as they can provide insight into the machine’s durability and performance. Balancing your budget with your requirements will help you make an informed decision.