Leave Your Message

In recent years, the demand for efficient food preservation methods has surged, propelling the vegetable dryer machine into the spotlight as an essential appliance for both home cooks and commercial establishments. According to a report by the Food and Agriculture Organization (FAO), about one-third of food produced globally is wasted, resulting in significant economic losses and environmental impact. This highlights the necessity for effective drying methods that can extend the shelf life of vegetables while preserving their nutritional value.

As the market for food dehydration continues to expand, statistics indicate that the global food dehydrator market is projected to grow at a compound annual growth rate (CAGR) of 8.5% from 2021 to 2025. This growth underscores the increasing recognition of vegetable dryer machines as vital tools for reducing food waste, enhancing food security, and improving storage capabilities. With a plethora of options available, selecting the right vegetable dryer machine can be daunting. Therefore, understanding key features, processing capacities, and energy efficiency is crucial in making an informed decision, whether for personal use or business applications.

In conclusion, as consumers become increasingly aware of sustainability and health, the vegetable dryer machine stands out as a practical solution that addresses both needs. By evaluating performance metrics and considering specific requirements, individuals and businesses alike can effectively choose a machine that best meets their objectives in preserving the quality and integrity of vegetables.

When considering a vegetable dryer machine for either home or business use, understanding the types and features available is crucial to making the best choice. Vegetable dryers can primarily be classified into two categories: conventional and advanced dehydrators. Conventional models typically use ambient heat and airflow, while advanced dehydrators employ infrared or microwave technology to speed up the drying process. According to a report by Market Research Future, the global food dehydrator market is anticipated to grow at a CAGR of 6.02% from 2020 to 2027, indicating a rising interest in efficient food preservation methods.

Key features to look for include temperature control settings, drying capacity, and energy efficiency. Temperature control allows users to tailor the drying process to different vegetables, preserving nutrients more effectively. A larger capacity is essential for businesses that require high throughput, while energy-efficient models are particularly important for home users seeking to reduce electricity consumption. As highlighted in a survey conducted by the USDA, dehydrated fruits and vegetables retain approximately 90% of their original nutrients, emphasizing the importance of selecting a machine that ensures optimal drying conditions.

Tips for choosing the right vegetable dryer include evaluating your specific needs – whether you're drying for personal use or commercial distribution. Higher wattage typically translates to faster drying times, and it’s beneficial to select models with adjustable trays for diverse vegetable sizes. Additionally, consider opting for systems with noise reduction features for a quieter operation, especially if the machine will be used in a home setting.

When selecting the best vegetable dryer machine for home or business use, several key factors must be carefully considered to ensure optimal performance and efficiency. One of the most important elements is the drying capacity of the machine. According to industry reports, the global dehydrated vegetables market is projected to reach $30 billion by 2026, driven by increasing consumer demand for healthy and preserved food options. A suitable dryer must be able to handle your specific volume needs, whether drying small batches for personal use or larger quantities for commercial operations.

Another crucial consideration is the energy efficiency of the vegetable dryer. Machines that utilize advanced drying technologies, such as convection or freeze-drying, can significantly reduce energy consumption. Research indicates that energy-efficient models can lower operational costs by up to 40%, making them a more sustainable choice for both home cooks and food businesses. Additionally, look for machines that offer adjustable temperature settings and timer controls, which can further optimize the drying process based on the type and moisture content of the vegetables being processed. By focusing on these essential factors, you can make an informed decision that best suits your drying needs.

When it comes to choosing the right vegetable dryer machine, understanding the differences between home and commercial models is crucial. Home vegetable dryer machines are typically smaller, designed for personal use, and feature simpler controls. They often have a lower drying capacity, making them suitable for small batches of fruits and vegetables. These machines may also offer energy-efficient options, which can be particularly appealing for households that seek to preserve food without incurring high energy costs. Moreover, home models usually come with additional features such as adjustable temperature settings and timer functions, providing users with flexibility and convenience for their drying needs.

On the other hand, commercial vegetable dryer machines are built for higher efficiency and larger production scales, catering to businesses that require the bulk drying of vegetables. These machines tend to have advanced technological features, such as specialized drying chambers that enhance airflow and heat distribution, ensuring even drying across all produce. Consequently, they can handle larger quantities at once, which is essential for restaurants, food manufacturers, and distributors. Additionally, commercial units often incorporate more robust materials and construction to withstand continuous, heavy use, thus offering longevity and reliability in demanding environments. Overall, the choice between home and commercial vegetable dryer machines hinges on the user's specific needs, production quantity, and intended application.

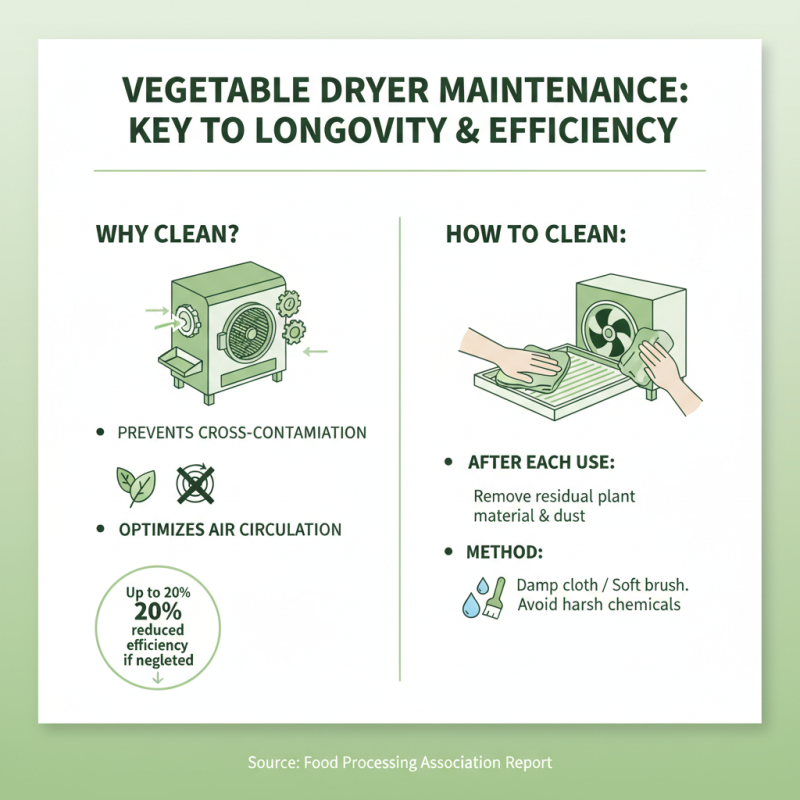

Maintaining your vegetable dryer machine is crucial for ensuring its longevity and efficiency, whether for home or business use. Regular cleaning is one of the primary maintenance tasks that should not be overlooked. According to a report from the Food Processing Association, neglecting routine cleaning can reduce the efficiency of drying machinery by up to 20%. It's essential to remove residual plant material and dust after each use to prevent cross-contamination and ensure optimal air circulation. Using a damp cloth or a soft brush can help keep the machine's components in good condition without causing damage.

Another vital aspect of maintenance involves checking and replacing any worn-out parts regularly. A study by the International Journal of Agricultural Engineering highlighted that replacing worn dryer belts and seals can improve energy efficiency by 15%, leading to significant cost savings in the long run. It's also recommended to keep the machine in a dry and well-ventilated area to prevent moisture buildup, which can contribute to deterioration. Moreover, scheduling routine professional check-ups, at least once a year, can help identify potential issues before they escalate, ensuring your vegetable dryer operates at peak performance for years to come.

When selecting the best vegetable dryer machine in 2025, it’s important to explore various top brands and models available on the market. The leading options typically showcase robust features that cater to both home users and businesses. Many of these machines offer adjustable temperature settings and multiple drying modes, providing versatility for different types of vegetables. For instance, some models feature digital displays and timers, allowing users to monitor the drying process with precision.

In addition to functional attributes, reliability and user reviews play a crucial role in deciding which vegetable dryer to choose. Many consumer choices are influenced by machine efficiency, energy consumption, and ease of use. Among the innovative designs, some models stand out for their stackable trays, which maximize drying space without occupying much countertop territory. This feature is particularly beneficial for businesses that require high-capacity drying.

As 2025 approaches, staying informed about evolving technology in vegetable drying can help ensure that users pick machines that will meet their culinary or commercial needs effectively.