Leave Your Message

In today's fast-paced industrial landscape, companies are continuously seeking innovative solutions to enhance operational efficiency and reduce energy costs. One such breakthrough is the use of Compressed Air Heaters, which have been shown to improve the performance of compressed air systems significantly. According to a report by the International Energy Agency (IEA), industrial heating accounts for nearly 30% of global energy consumption, a substantial portion that can be optimized through advanced technologies. By integrating Compressed Air Heaters, facilities can achieve energy savings of up to 50%, while also reducing environmental impact, as highlighted by a recent study from the American Society of Mechanical Engineers (ASME).

In today's fast-paced industrial landscape, companies are continuously seeking innovative solutions to enhance operational efficiency and reduce energy costs. One such breakthrough is the use of Compressed Air Heaters, which have been shown to improve the performance of compressed air systems significantly. According to a report by the International Energy Agency (IEA), industrial heating accounts for nearly 30% of global energy consumption, a substantial portion that can be optimized through advanced technologies. By integrating Compressed Air Heaters, facilities can achieve energy savings of up to 50%, while also reducing environmental impact, as highlighted by a recent study from the American Society of Mechanical Engineers (ASME).

These heaters not only improve the overall efficiency of compressed air usage but also extend equipment lifespan and enhance productivity across various industrial applications. As organizations increasingly focus on sustainability and cost-effectiveness, the adoption of Compressed Air Heaters stands out as a pivotal strategy for modern industry.

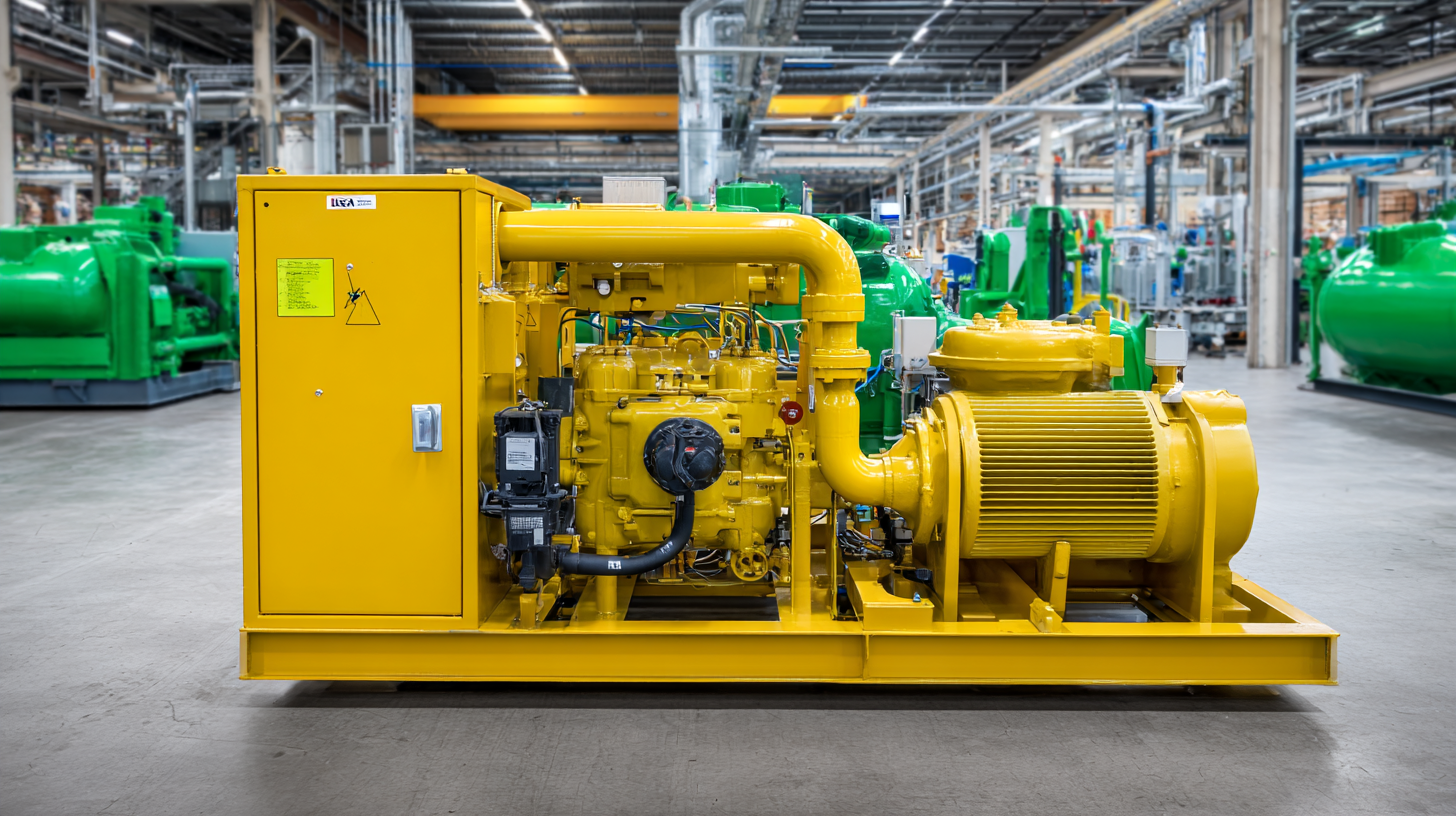

Compressed air heaters are playing a crucial role in maximizing energy efficiency within industrial operations. By converting compressed air into a reliable source of heat, these systems minimize heat loss typically associated with traditional heating methods. This innovative approach not only ensures that the desired temperatures are reached more quickly but also reduces the overall energy consumption of industrial plants. As a result, companies can achieve significant cost savings while maintaining high productivity levels.

Moreover, the integration of compressed air heaters leads to enhanced process reliability. Traditional heating solutions may suffer from fluctuations in temperature, which can adversely affect the quality of products. In contrast, compressed air heaters provide a consistent and controllable heat source, which is essential for processes that require precision. This reliability fosters improved operational efficiency, allowing businesses to streamline their manufacturing processes and minimize downtime, ultimately leading to a more environmentally friendly production model.

In today's competitive industrial landscape, reducing downtime is crucial for maximizing productivity and profitability. Compressed air heaters have emerged as an innovative solution to enhance equipment reliability and minimize the risks of failures. According to a report by the Compressed Air and Gas Institute (CAGI), improper temperature management in compressed air systems can lead to moisture accumulation, resulting in up to 30% of air system inefficiencies. By maintaining optimal air temperatures, compressed air heaters prevent condensation that could potentially damage pneumatic components, ensuring consistent operation and reliability.

Furthermore, a study by the Department of Energy (DOE) highlighted that up to 70% of compressed air systems in manufacturing facilities are undersized or poorly maintained. Implementing compressed air heaters can improve system performance by providing necessary warmth to the air, increasing overall energy efficiency by up to 25%. This can significantly reduce wear and tear on equipment, thereby extending the lifespan of critical machinery. By investing in compressed air heating technology, industries not only enhance their operational efficiency but also create a more reliable and resilient production environment.

The integration of compressed air heating systems in manufacturing presents a compelling case for cost savings and enhanced efficiency. By evaluating the return on investment (ROI) of these systems, industries can uncover significant economic benefits. The improvement of compressed air systems is particularly crucial as leaks and inefficiencies can lead to wastage of energy and resources. Implementing leak detection and repair programs can reduce compressed air waste by up to 50%, resulting in noticeable energy savings and cost reductions.

Moreover, the optimization of industrial compressed air energy storage performance is essential. Recent studies emphasize the importance of a novel exergoeconomic framework that considers pressure-temperature dependent cost analysis. This could lead to better investment decisions regarding compressed air systems and highlight the interplay between multi-stage compression and expansion efficiencies. By focusing on such optimizations, manufacturers can maximize operational efficiency, ultimately leading to a more sustainable and cost-effective production process.

Compressed air heaters play a vital role in process engineering by optimizing temperature control across various industrial applications. These innovative devices enable precise heating of air, which is crucial for maintaining optimal operational conditions in processes that require consistent temperature levels. By ensuring that the compressed air reaches the desired temperature before it enters the production process, companies can improve the efficiency of equipment and reduce energy consumption.

Moreover, the use of compressed air heaters minimizes the risk of product defects that can arise from temperature fluctuations. This stability not only enhances product quality but also leads to less downtime and maintenance requirements for machinery. As industries push for higher productivity and improved operational efficiencies, the integration of compressed air heaters into their systems becomes increasingly essential, streamlining processes and reducing overall operational costs.

Compressed air heating solutions are gaining attention for their significant environmental benefits in industrial settings. By utilizing compressed air as a heating medium, industries can reduce their dependence on traditional fossil fuels, leading to lower carbon emissions. As companies strive to meet sustainability targets, compressed air heaters stand out by promoting energy efficiency and reducing greenhouse gas emissions throughout the production process.

Furthermore, these systems optimize energy use by converting compressed air directly into heat, minimizing energy loss associated with conventional heating methods. When industries invest in compressed air heating, they not only enhance productivity but also contribute to a greener economy. The ability to harness an existing resource like compressed air helps to reduce overall energy consumption, making it a smart choice for companies aiming to balance operational efficiency with environmental responsibility.