Leave Your Message

When it comes to post-harvest processes, the importance of selecting the right rice dryer cannot be overstated. A rice dryer is essential for reducing moisture levels in harvested grains, which directly affects the overall quality, flavor, and shelf life of the rice. Choosing the appropriate drying equipment can enhance efficiency and minimize losses during storage, making it a vital decision for farmers and suppliers alike.

In an agricultural landscape where quality and sustainability are paramount, understanding the different types of rice dryers available is crucial. Factors such as drying technology, energy consumption, and capacity should all be taken into consideration when making your choice. By evaluating each option based on your specific harvest needs, you can ensure optimal results and protect your investment in your rice crop.

This article aims to provide essential tips for selecting the right rice dryer tailored to your unique requirements. From assessing your operational goals to understanding the technical specifications, we will guide you through the key considerations that will help you make an informed decision for successful rice production.

When selecting a rice dryer for your harvest needs, it's essential to consider several key factors to ensure optimal performance and efficiency. First, assess the capacity of the dryer in relation to your harvest size. A dryer that can accommodate your total rice production will significantly improve your workflow, reducing the time required for drying and enabling you to process more grain in less time. Additionally, consider the moisture removal rate of the dryer, as this will determine how quickly and effectively the rice can be dried to the desired level.

Another critical factor is the energy efficiency of the dryer. Look for models that utilize advanced technology to minimize energy consumption while maximizing drying performance. This not only helps lower operational costs but also reduces the overall environmental impact. Lastly, evaluate the ease of operation and maintenance. A user-friendly interface and accessible components for cleaning and maintenance will ensure that you can operate the dryer effectively, prolonging its lifespan and reducing downtime during peak harvesting periods. By carefully considering these factors, you can choose a rice dryer that meets your specific needs and enhances your overall harvest experience.

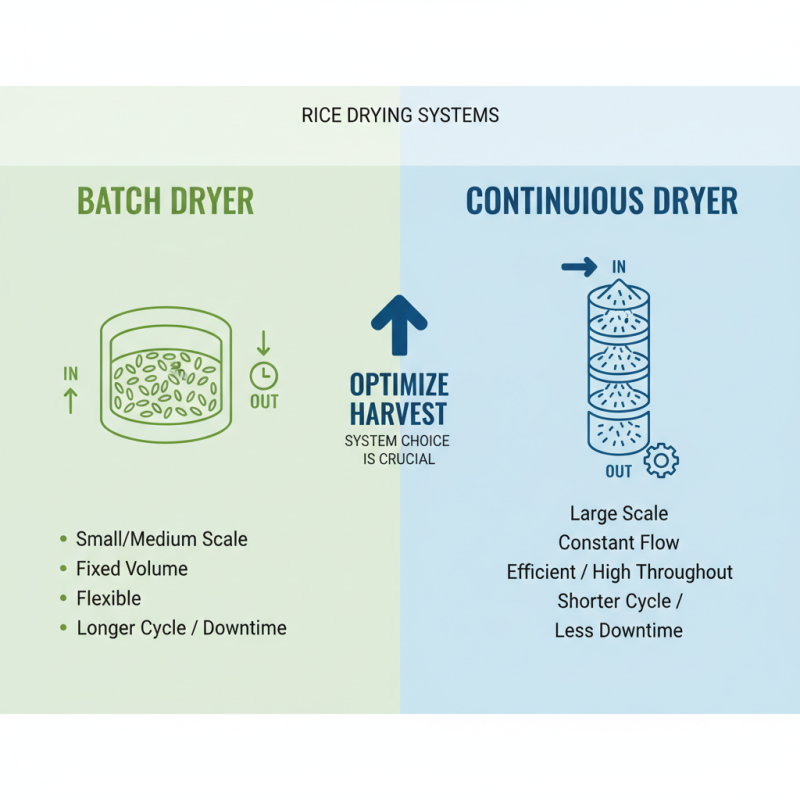

When selecting a rice dryer, understanding the differences between batch and continuous drying systems is crucial for optimizing your harvest. Batch rice dryers operate on a fixed schedule, where a specified amount of rice is loaded into the dryer at once. This method is often favored by small to medium-scale operations because it allows for flexibility in processing different volumes of rice. However, the drying cycle in batch systems can be time-consuming, requiring operators to wait until one load is finished before beginning another. This can lead to downtime, especially during peak harvest periods.

On the other hand, continuous rice dryers offer a more streamlined approach by allowing rice to be fed into the system continuously while dried rice is simultaneously discharged. This design significantly increases efficiency and throughput, making it ideal for larger operations or those processing rice on a commercial scale. Continuous dryers often maintain a consistent moisture content, reduce the risk of over-drying, and can handle varying input sizes without interrupting the drying process. However, they generally come with a higher initial investment and may require more complex maintenance protocols.

Choosing between batch and continuous rice dryers ultimately depends on your specific needs, including the scale of production, budget constraints, and desired efficiency. Understanding these differences can help you make an informed decision that aligns with your operational goals.

When selecting a rice dryer, one of the critical factors to consider is its drying capacity, as this directly impacts efficiency and cost-effectiveness in post-harvest management. According to the United Nations Food and Agriculture Organization, rice production has been steadily increasing, with global output reaching approximately 500 million tons annually. This rise emphasizes the need for efficient drying solutions to manage the vast quantities that require processing. A dryer’s capacity is typically measured in tons per hour, and it's essential to choose one that meets your specific harvest size. For instance, if you are handling a harvest of 100 tons, a dryer with a capacity of 5 tons per hour will necessitate 20 hours of operation to process the entire batch.

Furthermore, operational efficiency can be further analyzed through moisture removal rates. An effective rice dryer should be able to reduce moisture content from 25% to the ideal 13% within a reasonable timeframe. Industry reports have shown that advanced models can achieve this moisture reduction in as little as 3 hours for a capacity of 10 tons per hour, enabling producers to optimize their workflow and reduce spoilage. Ultimately, understanding the drying capacity not only informs purchasing decisions but also aligns with the broader objectives of maximizing quality and profitability in rice production.

When selecting a rice dryer that meets your harvest needs, understanding energy efficiency ratings is crucial. According to the International Rice Research Institute (IRRI), energy consumption during the drying process can account for up to 15% of the total post-harvest costs. Therefore, opting for a rice dryer with superior energy efficiency not only reduces operational costs but also supports sustainable agricultural practices. For instance, advanced technologies such as heated air dryers with variable speed fans can offer a 30% reduction in energy usage compared to conventional dryers.

Furthermore, different drying technologies exhibit varying energy efficiency levels. A study from the Agricultural Research Service suggests that using a continuous flow dryer, which operates on a more optimized heating system, could enhance energy efficiency ratings significantly. This dryer type can achieve over 70% efficiency, compared to batch dryers that might only reach around 50%. By comparing the efficiency metrics of these technologies, farmers can make informed decisions that align operational efficiency with their economic goals while minimizing the environmental impact. Hence, assessing energy ratings and technological advancements is essential for choosing the right rice dryer to enhance productivity and reduce costs effectively.

When selecting a rice dryer, ensuring its maintenance and longevity is crucial to maximize its performance over time. Industry studies indicate that regular maintenance can extend a dryer’s lifespan by up to 40%. This includes routine cleaning, inspection of electrical components, and checking for wear and tear on mechanical parts. Implementing a proactive maintenance schedule not only reduces downtime but also enhances energy efficiency and product quality, minimizing losses during harvest.

Moreover, understanding the operational environment plays a significant role in optimizing dryer performance. Data from agricultural engineering journals suggest that high humidity levels can severely impact the efficiency of rice drying systems. Therefore, installing humidistat controls can help maintain optimal drying conditions, thereby reducing the need for repairs and adjustments. Additionally, adhering to manufacturer guidelines on usage and maintenance can further bolster the durability of the equipment and prevent costly breakdowns, ensuring that the investment yields maximum returns throughout its operational life.